Learning how to read dimensions is a very important skill. You need it when you design custom packaging for a new product, figure out shipping costs, or simply find the right-sized box to mail a gift. Getting the dimensions right is essential.

A small mistake in measurement can lead to wasted materials, higher costs, and products that do not fit. For any business, correctly measuring and communicating box dimensions is a basic and important skill.

This guide will show you the industry-standard methods for reading dimensions. It will help make sure your measurements are accurate and clearly understood every time.

How to Read Dimensions of Different Kinds of Packaging

To read packaging dimensions correctly, you first need to know if the item is flat or has depth. Flat items, like a label or a paper insert, are considered two-dimensional (2D) and only need two measurements. Objects like a box or the product are three-dimensional (3D) and always require three measurements to be described accurately.

How to Read Dimensions of a Box

When you see box dimensions, they are always written in a special order. The industry standard is:

Length x Width x Depth (L x W x D)

Sometimes, people use Height instead of Depth, so you might also see:

Length x Width x Height (L x W x H)

Here is how to find each measurement. Always measure the box with its opening facing up.

- Length (L): This is always the longest side of the box’s opening.

- Width (W): This is the shorter side of the box’s opening.

- Depth (D) or Height (H): This tells you how deep the box is. It is the measurement from the top opening down to the bottom of the box.

Applying this to different boxes:

- How to Read Dimensions of a long box:

How to measure it:

Again, look at the opening at the top. It is a long, narrow rectangle. The sides are 15 inches and 3 inches.

Length is the longest side of that opening. So, the Length is 15″.

Width is the shorter side of the opening. So, the Width is 3″.

Height is how deep the box is. So, the Height is 4″.

Following the L x W x H rule, the final measurement is 15″ x 3″ x 4″.

- How to Read Dimensions of a Tall Box:

Look at the small opening at the top of the box. Its sides are 4 inches and 3 inches.

Length is the longest side of the opening. So, the Length is 4″.

Width is the shorter side of the opening. So, the Width is 3″.

Height is the tall measurement, from the bottom to the top opening. So, the Height is 13″.

Even though 13″ is the biggest number, it is the Height, so it must be written last. This is why the correct dimension is 4″ x 3″ x 13″.

- How to Read Dimensions of a Standard Box:

First, look at the opening at the top of the box. It has two sides, 15 inches and 10 inches.

Length is the longest side of the opening. So, the Length is 15″.

Width is the shorter side of the opening. So, the Width is 10″.

Height is how tall the box is, from the bottom to the top. So, the Height is 9″.

When you write it down, you follow the rule: Length x Width x Height. That is why it is 15″ x 10″ x 9″.

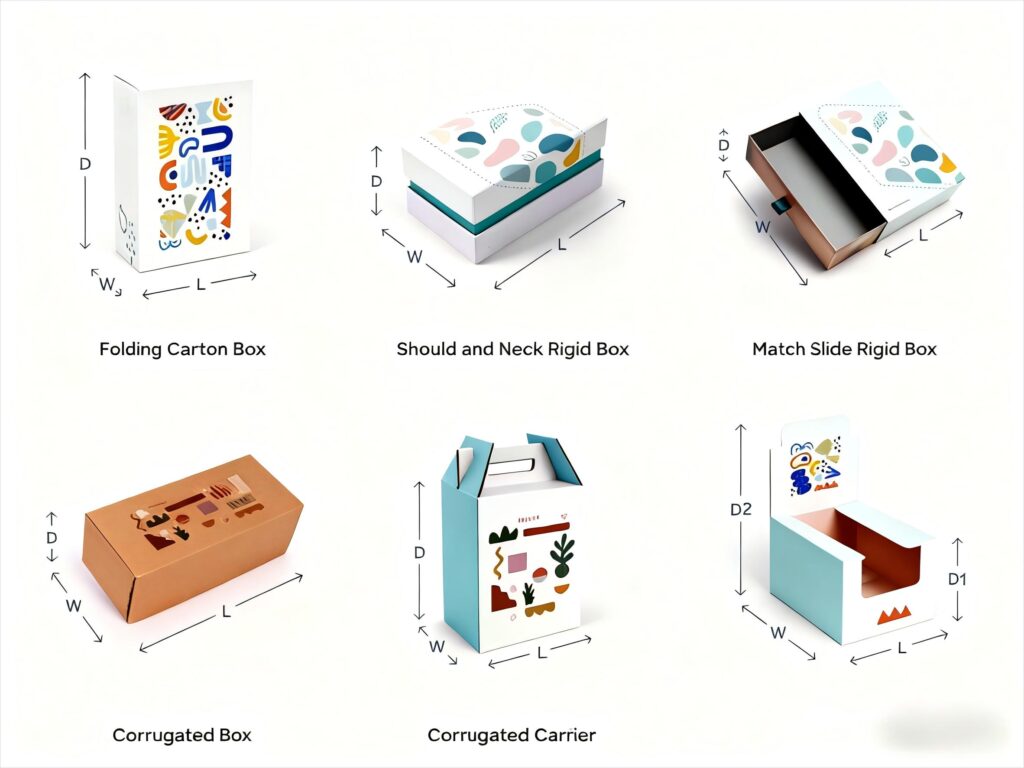

Now that you understand the basic rule for standard boxes, let’s look at a few other common styles. Boxes like mailers, folders, and telescoping boxes are measured in a similar way, but it helps to know exactly where to find the Length, Width, and Depth for each unique design. Here is how to measure them.

How to Read Dimensions of 2D Items (Banners, Designs, etc.)

For flat, two-dimensional (2D) items like a rectangular banner, a paper label, or a digital design file, you only need two measurements: Length and Width. These are typically written as Length x Width.

The rule for identifying them is very simple: Length is always the longer side, and Width is always the shorter side.

The Length tells you how long the item is, while the Width (which is sometimes called Breadth) tells you how wide or broad it is. This standard helps avoid any confusion, no matter how you turn or look at the rectangle.

For example, imagine you need to order a rectangular banner and its sides measure 20 inches and 5 inches.

- Because Length is the longer side, Length is 20 inches.

- Because Width is the shorter side, Width is 5 inches.

Therefore, the correct dimensions for the banner would be written as 20″ x 5″.

What You Need to Consider When Reading Dimensions for Custom Packaging

One of the most frequent and serious errors in packaging is using the wrong type of dimension. For example, designing a product box based on its outer dimensions, only to find the product won’t fit inside.

To prevent these issues, you must first clearly understand the definition and purpose of two distinct dimension types:

1. Inner Dimensions (ID): The “Safe Space” That Determines if a Product Fits

The Inner Dimension (ID) refers to the usable, empty space inside a package (Length x Width x Height). Its primary purpose is to accommodate the product along with any protective cushioning materials perfectly

When calculating the required inner dimensions, you must not use the product’s standard “nominal” size.

Instead, you must account for the product’s absolute maximum size (including any protrusions) and add the thickness of any cushioning materials (like foam, inserts, or bubble wrap) on all sides. For the Rigid packaging and also the corrugated packaging are very important.

2. Outer Dimensions (OD): The “Cost Ruler” That Determines Your Expenses

The Outer Dimension (OD) is the overall measurement of the package from the outside (Length x Width x Height). This dimension includes the thickness of the packaging material itself. Its primary purpose is to fit within the logistics and shipping ecosystem.

Outer dimensions are critical for calculating costs. You must check them against the standards set by your logistics partners. Shipping carriers have pricing tiers based on size, warehouses have specific shelf heights, and pallets have standard footprints.

Exceeding these standards, even by a small amount, can lead to significant extra costs. Accurate dimensions are crucial in e-commerce to optimize shipping costs, as oversized packages can increase fees by up to 30% due to dimensional weight pricing

Ready To get Custom Packaging ?

Contact us with a Lower Quantity

Summary

Remember these two simple rules for your packaging. First, always list the size as Length x Width x Height. Second, the inside size is to make sure your product fits, and the outside size affects your shipping cost.

Even a tiny mistake in these sizes can cause big problems, like broken products or paying extra money for shipping.

Don’t let small mistakes create major problems. For expert packaging solutions that are precise, protective, and cost-effective, contact Letai Packaging today.

- The Different Types of Packaging Foam – Packaging Foam 101 - October 16, 2025

- What are Packaging Inserts The Ultimate Guide - October 16, 2025

- What is Kraft Paper? A Comprehensive Guide to Its Use in Packaging - October 16, 2025